High Energy Ball Milling How It Works | Union .

High Energy Ball Milling In discussions on high energy ball milling, the more generic term "ball mills" is often used in place of the terms "stirred ball .

WhatsApp)

WhatsApp)

High Energy Ball Milling In discussions on high energy ball milling, the more generic term "ball mills" is often used in place of the terms "stirred ball .

: +49(0) 0 Fax No.: 7 page II5 II3 Devices in use: Shaker Mill, Simoloyer ®, Planetary Ball Mill, Attritor, Drum/Ball–Mill For the high kinetic processing techniques a various number of milling ...

USE OF BALL MILLING Generation of curved or closedshell carbon nanostructures, carbon scrolls by ballmilling of graphite Nanoporous carbon by ball milling Carbon nanotubes and carbon microspheres by high energy ball milling ...

Do you want to show high energy ball milling or other products of your own company? Display your Products FREE now!

Highenergy ball milling is a simple, effective and productive way to produce various nanocrystal powders in highenergy planetary, ball and vibratory mills. Other things being equal, the higher the intensity and duration of grinding and ...

Preparation of Nb3Al by highenergy ball milling and superconductivity Yongliang Chen1*, Zhao Liu1, Pingyuan Li1, Xiaolan Zhang1, Suhua Yang1, Dawei Yang1, Lupeng Du1, Yajing Cui1, Xifeng Pan2, Guo Yan2 and Yong Zhao1,3 1 Key Laboratory of Magnetic Levitation Technologies and Maglev Trains, Ministry

Download and Read High Energy Ball Milling Mechanochemical Processing Of Nanopowders Woodhead Publishing In Materials life plant based edition customer visits building a better market focus de lama die naar het westen kwam ...

Mechanochemical processing is a novel and cost effective method of producing a wide range of nanopowders. It involves the use of a high energy ball mill to initiate chemical reactions and structural changes. High energy ball milling ...

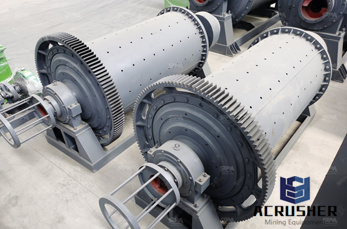

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ...

Chapter 2 HighEnergy Milling Introduction Particle size reduction, or comminution is an important step in many technological operations. The process itself is defined as the mechanical breakdown of solids into smaller particles ...

high energy ball milling/Grate Ball Mill/Overflow Type Ball ... Benefication Equipment Construction Material Production Equipment Crusher Equipment Ball Mill Ball mill is the key equipment for secondary grinding after crushing. » Learn More

Metal matrix multicomponent alloys and others based on the Ti+Ti 6 Si 2 B phases are potentially attractive for structural applications. However, there is limited information in literature on the effect of alloying in stability of the Ti 6 Si 2 ...

On Aug 1, 2017 M. Debata (and others) published: Effect of high energy ball milling on structure and properties of 95 heavy alloys See all › 13 References Request fulltext Effect of high energy ball milling on Article ...

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles. ... The E max is an entirely new type of ball mill for high energy milling. The unique ...

High energy ball milling process for nanomaterial synthesis... the planetary ball mill can be used for highspeed ... highenergy ball milling process has attracted much attention and inspired numerous research ... » Learn More High ...

Highenergy ball milling to enhance the reactivity of aluminum nanopowders B. Andréa, M.V. Couleta, P.H. Espositoa,finob, R. Denoyelb,n a AixMarseille Université, CNRS, IM2NP UMR 7334, Campus de Saint Jérôme, 13397 ...

production of nanostructured metal matrix composite powders. The strong energy transfer is capable to activate chemical reactions (reactive milling) [3]. Metal matrix composite powders produced by high energy ball milling feature a ...

Highenergy ball milling Mechanochemical processing of nanopowders Editedby MalgorzataSopickaLizer CRCPress BocaRaton Boston NewYork Washington,DC WOODHEAD PUBLISHING ... Contents Contributorcontactdetails xi ...

2017/08/06· Chapter 2 HighEnergy Milling Introduction Particle size reduction, or comminution is an important step in many technological operations. The process itself is defined as the mechanical breakdown of solids ...

76 Tsipas et al. EVect of high energy ball milling on titanium– hydroxyapatite powders 6 Comparison of room temperature XRD patterns for Ti– 20 wt%HA, balled milled for 1 hour, before and //

STUDY ON THE EFFECT OF HIGH ENERGY BALL MILLING (A NANO MATERIAL PROCESS) ON THE MICROSTRUCTURE AND MECHANICAL PROPERTIES OF A (AlSiFeCu) ALLOY A THESIS SUBMITTED IN PARTIAL ...

2010/05/24· Mechanochemical processing is a novel and cost effective method of producing a wide range of nanopowders. It involves the use of a high energy ball mill to initiate chemical reactions and structural changes. High energy ...

High energy ball milling is proposed for easy processing of OMt in bulk. • Structural changes of OMt were analyzed with ball milling under varying rpm time. • Exfoliation of the clay platelets was indicated for ball milling at 400 rpm ...

Brochure More information from HighEnergy Ball Milling Description: Mechanochemical processing is a novel and cost effective method of producing a wide range of

WhatsApp)

WhatsApp)