Ball Mills, Ball Milling Equipment British Rema

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

WhatsApp)

WhatsApp)

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

Now the mill steel ball on the market can be divided into two types according to the manufacturing process technology: Casting and forging. But the wear degrees are ...

• Various types of Attritors can be used in wet or dry grinding process. ... The theoretical critical speed of a ball mill is the speed at which the centrifugal ...

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, M. Yang UNION PROCESS INC. Akron, Ohio Presented by Robert "Bob" Schilling Presented at the .

The LumberMate LM29 portable sawmill is a customizable personal bandsaw mill capable of milling hardwood softwood logs up to 29'''' in diameter.

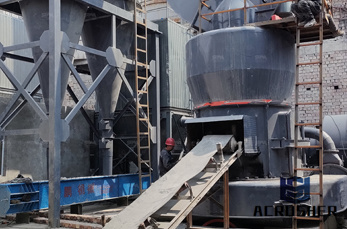

Introduction Dry process ball mill consists of feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and ...

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

Primary Metals Ball Mill Discharge, Sag Mill Discharge, Tailings, Cyclone Feed; Coal Preparation Heavy Media, Hydrocyclone, Cyclone Feed, Thickener Underflow

Dry ball mill can work without adding water, which is the key point to distinguish dry and wet ball mill. Dry ball mill is a straight cylinder, which is provided with ...

Ball Screws: Ball Screws Select from the dropdown menus below (in any order) to determine the appropriate Ball Screw model. SPEC 1 DIAMETER: Select .375 .500

Union Process can help you identify the right laboratory ball mill for your application. Contact us now to put our expertise to work for you

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

A ball mill is a type of grinder used to grind and ... the mechanical alloying process ... other materials either wet or dry. There are two kinds of ball mill, ...

Wet And Dry Process Ball Mill,Cement Plant Ball Mills Manufacturer, Find Complete Details about Wet And Dry Process Ball Mill,Cement Plant Ball Mills Manufacturer ...

Aciera F1: Sixis 101: SIP: Conversion of Chinesemake watchmakers lathe into micromill

How is cement manufactured? Learn cement manufacturing process thoroughly.

A stamp mill (or stamp battery or stamping mill) is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or ...

Overview. This highly versatile, singledisk attrition mill can be used in multiple production and laboratory applications for both food and industrial products.

Open the lid to your Ball Mill and add the following: 150 grams of Potassium Nitrate, 30 grams of Charcoal Powder, and 20 grams of Sulfur ( if your lead balls are not ...

A ball mill can also be helpful in the process of cold welding, ... The ball mill can be used in the processing of wet or dry materials, ... FAB 3R. All rights ...

How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder.

Products > Three Roll Mills > Three Roll Mill How the Three Roll Mill Works. The material to be milled is placed between the feed and center rolls.

pre drying chamber cement mill Grinding Mill China. ball mill dry process india,ball mill drying chamber plaques Description high production efficiency; diagram of a ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

WhatsApp)

WhatsApp)